Table of Contents

Inventory management can make or break your business. Whether you’re running a local shop or managing a national operation, getting a handle on your stock is key to keeping things running smoothly. In this guide, we’ll dive deep into how you can streamline your inventory processes, save on costs, and make sure you’ve got the right stock at the right time. With the right tools and strategies, Aussie businesses of all sizes can boost efficiency and stay ahead in a competitive market. Let’s get into it.

Introduction to Inventory Management

Inventory management is all about keeping track of the goods and materials a business has on hand. It involves overseeing the flow of stock from suppliers through to customers. This includes ordering, storing, and using inventory efficiently. Essentially, it’s about ensuring you have the right amount of stock at the right time to meet customer demand without overstocking or running out.

Importance of Effective Inventory Management in Business

Effective inventory management is crucial for any business. It directly impacts your bottom line by balancing supply and demand, reducing costs, and improving cash flow. When done right, it ensures that you have just the right amount of stock to fulfil customer orders without tying up too much of your capital. This can lead to increased sales, better customer satisfaction, and a healthier profit margin. For instance, in Australian businesses, especially those with seasonal fluctuations or diverse product ranges, efficient inventory management can be the key to staying competitive and responsive to market changes.

Challenges Faced by Businesses in Managing Inventory

Businesses face a unique set of challenges when it comes to inventory management. Geographic vastness and the need to service both urban and remote areas can complicate logistics and stock levels. Additionally, fluctuating demand due to seasonal trends, economic conditions, and market competition can make it tough to maintain optimal stock levels. Many businesses also grapple with outdated systems or manual processes that are prone to errors. Finding the right balance between having enough stock to meet demand and avoiding overstocking is a persistent struggle. Addressing these challenges often requires investing in modern technology and adopting best practices tailored to the market.

The Basics of Inventory Management

Types of Inventory

Understanding the different types of inventory is fundamental to effective management. Here’s a quick rundown:

Raw Materials: These are the basic materials that you use to create your products. For a manufacturer, this could be anything from metal sheets to fabric rolls. For retailers, it might be items purchased from suppliers to be sold directly.

Work-in-Progress (WIP): This inventory includes items that are in the process of being manufactured but aren’t yet finished. For instance, a car assembly line will have partially assembled vehicles as WIP inventory.

Finished Goods: These are products that are complete and ready for sale. This is what you see on store shelves or what’s ready for shipping out to customers.

Key Concepts: Reorder Points, Safety Stock, and Lead Time

To keep your inventory running smoothly, it’s essential to grasp a few key concepts:

Reorder Points: This is the stock level at which you need to place a new order to avoid running out of inventory. It’s calculated based on average sales and lead time, ensuring you have enough stock before it runs low.

Safety Stock: This is the extra inventory you keep on hand as a buffer against unexpected demand or delays in supply. It helps prevent stockouts and ensures you can meet customer demand even when things don’t go according to plan.

Lead Time: Lead time is the time it takes from placing an order with your supplier to receiving the stock. This includes everything from processing and shipping to handling. Knowing your lead time helps in planning when to reorder stock to avoid gaps.

Stocktaking: Why and How Often?

Stocktaking, or stock auditing, is the process of physically counting and verifying your inventory. It’s crucial for several reasons:

Accuracy: Regular stocktakes help ensure your inventory records match your actual stock. This accuracy is essential for making informed business decisions and maintaining customer satisfaction.

Loss Prevention: Regular counts can help identify discrepancies due to theft, damage, or administrative errors. Catching these issues early can save you from larger problems down the track.

Financial Reporting: Accurate inventory levels are critical for financial reporting and managing your cash flow. Inaccurate records can lead to incorrect financial statements and poor business decisions.

How often you should conduct stocktakes can depend on your business size and the volume of inventory. Smaller businesses might manage with quarterly or bi-annual stocktakes, while larger operations or those with high turnover might need to do it monthly or even weekly. Regardless of the frequency, regular stocktaking helps keep your inventory in check and your business running smoothly.

Why Inventory Management Matters for Businesses

Impact on Profitability and Cash Flow

Effective inventory management is a game-changer for your business’s profitability and cash flow. When you manage your stock well, you’re essentially ensuring that your capital is working for you rather than tying it up in excess inventory. Here’s how:

Boosted Profit Margins: By keeping just the right amount of stock, you reduce the costs associated with holding excess inventory, such as storage and insurance. This means your money is better spent, potentially increasing your profit margins.

Improved Cash Flow: Efficient inventory management prevents money from being unnecessarily tied up in stock that isn’t moving. This frees up cash to be used for other critical areas of your business, like marketing, expansion, or paying off debt.

Reduced Overstocking and Stockouts: Proper inventory management helps avoid the pitfalls of overstocking (which can lead to obsolescence and markdowns) and stockouts (which can result in lost sales and disappointed customers). Both scenarios negatively impact your bottom line.

Benefits of Having the Right Stock at the Right Time

Getting your inventory levels just right isn’t just about avoiding problems; it’s about seizing opportunities and driving your business forward. Here’s why having the right stock at the right time is crucial:

Enhanced Customer Satisfaction: When you have the products your customers want, when they want them, you’re more likely to keep them coming back. Effective inventory management helps you meet customer demand consistently, leading to happier clients and repeat business.

Increased Sales and Revenue: With the right stock levels, you’re better positioned to take advantage of sales opportunities and promotions. This means you can maximise sales and revenue without the risk of missing out due to stock shortages.

Optimised Operations: Having the right amount of stock simplifies your operations. It reduces the need for last-minute rush orders or storage challenges and allows for smoother, more predictable business processes.

Strategic Advantage: Businesses that manage their inventory effectively can respond more swiftly to market trends and changes in customer preferences. This agility can give you a competitive edge in a rapidly evolving market.

In a nutshell, getting your inventory management right isn’t just about avoiding problems; it’s about positioning your business for success. By ensuring you have the right stock at the right time, you can boost profitability, improve cash flow, and provide better service to your customers.

Modern Inventory Management Techniques

Just-in-Time (JIT) Inventory Management

The Just-in-Time (JIT) method is all about reducing waste and improving efficiency by receiving goods only as they’re needed for production or sales. With JIT, you’re not keeping piles of stock sitting around in a warehouse collecting dust. Instead, you’re working closely with suppliers to ensure stock arrives just in time to meet customer demand.

This approach works particularly well for businesses looking to minimise storage costs and avoid overstocking. However, it requires precise forecasting and strong relationships with reliable suppliers. If done right, JIT can significantly lower inventory costs and streamline your operations. But be aware, it also leaves less room for error, especially if there’s a hiccup in the supply chain.

Economic Order Quantity (EOQ)

The Economic Order Quantity (EOQ) formula is a classic inventory management technique that helps businesses determine the optimal order size to minimise the costs associated with ordering and holding stock. It’s all about striking that perfect balance – you don’t want to order too much and pay unnecessary storage fees, but you also don’t want to order too little and risk running out of stock.

EOQ takes into account factors like the cost of ordering inventory, holding costs (like warehousing), and demand. By calculating the most efficient order size, businesses can save money, improve cash flow, and avoid stockouts. It’s a handy tool for businesses of all sizes looking to optimise their purchasing decisions.

ABC Analysis and How to Categorise Stock Efficiently

ABC Analysis is a technique that helps businesses prioritise their inventory based on value. Not all stock is created equal, and ABC analysis is a way to categorise your inventory into three groups:

A-Items: These are your high-value products that make up the bulk of your revenue but usually don’t account for a large portion of your total inventory. Think of these as your big-ticket items or bestsellers. They require the most attention and close monitoring.

B-Items: These are moderately important items that contribute to a reasonable amount of your revenue. They sit between A and C items in terms of value and quantity. B-items need regular attention, but not as closely as A-items.

C-Items: These are your low-value items that may not contribute much to revenue, but you likely have a large number of them in stock. These require less frequent management and can be ordered in bulk.

Using ABC analysis allows businesses to focus on what matters most, ensuring that the most critical items get the attention they deserve. It helps you prioritise stock management efforts, save time, and reduce waste. For businesses managing a wide range of products, this technique is an absolute must for staying organised and efficient.

Cloud-Based Inventory Management Solutions

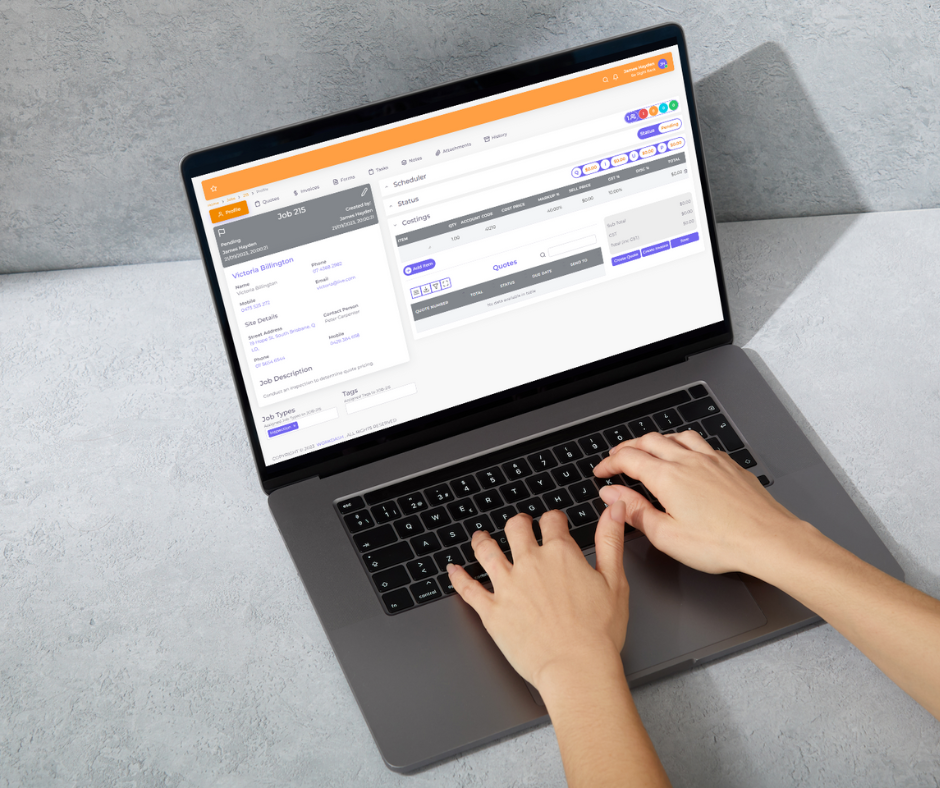

Cloud-based inventory management solutions offer businesses the flexibility and real-time insights needed to manage stock efficiently, without the headaches of manual tracking. With instant access to your inventory data from anywhere, cloud solutions make it easier to streamline operations, reduce costs, and keep your business running smoothly. Let’s dive into the key benefits and features you should look for.

Benefits of Cloud-Based Software for Real-Time Tracking

Cloud-based inventory management software has revolutionised how Aussie businesses keep tabs on their stock. With real-time tracking, you can see exactly what’s in your warehouse, on your shelves, or in transit—all from a single platform. This instant access means fewer stock discrepancies, quicker decision-making, and greater flexibility.

Whether you’re in the office or on the go, cloud software gives you 24/7 access to your inventory data from any device. You can spot potential stockouts before they happen, avoid over-ordering, and adjust your stock levels based on live data. Plus, with everything stored in the cloud, there’s no need for clunky servers or local storage. Your data is secure, always backed up, and accessible whenever you need it.

Features to Look for in Inventory Management Software

When choosing the right inventory management software for your business, you want to make sure it has the features to keep you ahead of the game. Here are a few essentials:

Real-Time Stock Tracking: This is non-negotiable. You need software that lets you track inventory in real-time so you always know what’s in stock and where.

Automated Reordering: Set reorder points and let the software do the heavy lifting. Automated reordering ensures you never run out of critical items and can even trigger purchase orders when stock gets low.

Multi-Warehouse Management: If your business has multiple locations, your inventory software should be able to manage stock across all sites seamlessly. Look for tools that let you transfer stock between warehouses or locations as needed.

Barcode Scanning Integration: Speed up stocktakes and reduce human error with barcode scanning integration. This feature is crucial for keeping your records accurate and up-to-date.

Customisable Reporting: You’ll want software that offers detailed reports on stock levels, sales trends, and order history, so you can make data-driven decisions and spot opportunities to improve.

Integrating Inventory Software with Other Business Systems

Your inventory system should play nicely with the rest of your business software. By integrating your inventory management solution with other systems like accounting software and CRM platforms, you can create a streamlined, unified workflow that boosts efficiency across the board.

Accounting Integration: When your inventory system is synced with your accounting software, you’ll get a clearer picture of your financials. Purchases, sales, and stock movements are automatically reflected in your accounts, helping you stay on top of cash flow and costs. It also makes end-of-year reporting much simpler.

CRM Integration: Connecting your inventory with your CRM means you can provide better service to your customers. When sales and customer data are linked with your stock levels, you can quickly check availability, provide accurate delivery estimates, and even automate order fulfilment. It’s a win for both your business and your customers.

Integrating these systems not only reduces the risk of manual errors but also improves overall efficiency, helping you focus more on growing your business and less on juggling multiple platforms.

Inventory Management for Small Businesses

For small businesses, managing inventory effectively can make all the difference between thriving and struggling. With limited resources, tighter margins, and less room for error, it’s crucial to have a solid inventory management strategy in place. Whether you’re managing stock from the back of your store or juggling orders in a home office, getting it right can help you save costs, improve cash flow, and keep customers happy.

Let’s explore the common challenges small businesses face and the tools and strategies that can help them stay on top of their stock.

Common Challenges Small Businesses Face

Small businesses often find inventory management a bit tricky. With limited staff, tighter budgets, and less room for error, getting it right can be a challenge. Some common issues small businesses face include:

-

Cash Flow Constraints: Many small businesses operate on a tight budget, so over-ordering can tie up much-needed cash in excess stock, while under-ordering can lead to missed sales opportunities.

-

Lack of Space: Smaller businesses often have limited storage, making it difficult to hold onto too much stock. This means they need to be smart about how much they order and when.

-

Manual Processes: Without advanced software or automation, small businesses often rely on manual processes, which are time-consuming and prone to human error.

-

Inconsistent Demand: Fluctuations in customer demand can leave small businesses scrambling to balance stock levels. One month, a product might fly off the shelves, while the next month it collects dust.

How to Keep Costs Down While Managing Stock Effectively

Managing inventory without breaking the bank is possible with a few smart strategies. For small businesses, it’s all about maximising efficiency and making the most of the resources available. Here are some ways to keep costs down:

-

Just-in-Time Ordering: By ordering stock only when needed, you can avoid holding too much inventory. This not only saves on storage costs but also frees up cash flow for other areas of your business.

-

Negotiate with Suppliers: Building strong relationships with your suppliers can help you negotiate better deals, whether it’s bulk discounts, longer payment terms, or flexible delivery schedules.

-

Batch Ordering: For items that you know will always sell, consider batch ordering. This allows you to take advantage of bulk discounts and reduce the frequency of reordering, which can save on shipping costs.

-

Minimise Waste: By accurately forecasting demand, you can reduce over-ordering and minimise the risk of excess stock going to waste. This is particularly important if you’re dealing with perishable goods.

Tools and Strategies Tailored for Small Enterprises

Small businesses don’t need large, complex systems to manage inventory effectively. There are plenty of affordable, easy-to-use tools and strategies designed specifically for smaller operations. Here’s what to consider:

-

Simple Cloud-Based Software: There are many affordable cloud-based inventory management tools that don’t require an IT department to run. Look for software with basic features like stock tracking, reorder alerts, and reporting—perfect for a small business.

-

Mobile-Friendly Solutions: For small businesses on the go, mobile-friendly inventory apps are a must. They let you manage stock, check orders, and track shipments right from your phone or tablet.

-

Barcode Scanning Apps: If you’re still using pen and paper or spreadsheets, it might be time to switch to a barcode scanning app. These tools are cost-effective and can save you hours on stocktakes while reducing human error.

-

Inventory Audits: Even for small businesses, regular stock audits are essential. A simple monthly or quarterly stocktake can help ensure that your records match up with what’s on the shelves, allowing you to spot discrepancies early.

By adopting these tools and strategies, small businesses can streamline their inventory management processes, reduce costs, and ultimately focus more on growing their business rather than worrying about stock levels.

Inventory Management for Enterprises

For large enterprises, managing inventory is a complex operation that spans multiple locations, warehouses, and product lines. Unlike smaller businesses, enterprises face unique challenges in ensuring stock is efficiently tracked, moved, and replenished at scale. Effective inventory management is crucial for minimising costs, meeting customer demand, and keeping supply chains running smoothly. With the right systems in place—like automation, data analytics, and supplier management—enterprises can optimise their stock control and stay competitive in today’s fast-moving market.

Handling Large-Scale Inventory Across Multiple Locations

For enterprises, managing inventory across multiple warehouses, stores, or even countries is no small feat. The complexity grows with the number of locations, product lines, and customers involved. Here’s how large-scale businesses can handle it:

Centralised Inventory Systems: Enterprises need a centralised system that provides visibility into stock levels across all locations. This allows businesses to transfer stock between locations, fulfil orders from the nearest warehouse, and avoid stockouts or overstocking in certain areas.

Multi-Warehouse Management: With stock spread across several locations, it’s essential to have software that can track inventory in real-time at each site. This enables efficient stock transfers and ensures that no location is overstocked or running on empty.

Location-Based Stock Allocation: By analysing sales data, businesses can allocate stock to different locations based on local demand. This means high-demand products are always available where they’re needed most, while slower-moving items aren’t clogging up valuable space.

Using Automation and Data Analytics to Optimise Inventory

Automation and data analytics are the backbone of modern enterprise inventory management. With large volumes of stock, it’s simply not possible to rely on manual processes. Here’s how automation and analytics can help optimise inventory:

Automated Reordering: Automated systems can monitor stock levels and automatically place orders when stock reaches pre-set reorder points. This reduces the risk of human error and ensures stock levels are maintained efficiently without manual intervention.

Demand Forecasting: Advanced inventory management systems use data analytics to forecast demand based on historical sales, market trends, and seasonality. This helps enterprises plan for peak seasons and avoid over-ordering during quieter periods, reducing the risk of dead stock.

Real-Time Reporting: Automated reporting tools provide real-time insights into stock levels, order history, and sales trends. With this data at their fingertips, businesses can make informed decisions about stock replenishment, product promotions, and supply chain adjustments.

RFID and Barcode Scanning: Many enterprises use RFID (Radio Frequency Identification) or barcode scanning to track stock movements in real-time. These technologies minimise human error during stocktakes and give an instant view of what’s on hand.

How to Manage Suppliers and Bulk Orders Efficiently

When managing large-scale operations, maintaining strong supplier relationships and managing bulk orders efficiently is crucial to keeping costs down and stock levels up. Here’s how enterprises can manage this aspect of inventory effectively:

Supplier Relationship Management (SRM): For enterprises, it’s critical to have solid relationships with suppliers. This means negotiating favourable terms, securing reliable lead times, and ensuring that suppliers can scale as your business grows. SRM tools can help manage communication and performance tracking with suppliers.

Bulk Ordering Benefits: Ordering in bulk can lead to significant cost savings for enterprises, but it requires careful planning to avoid overstocking. Using data-driven insights, enterprises can place bulk orders for high-demand products and lock in lower prices, while avoiding unnecessary bulk purchases for less popular items.

Supplier Diversification: Relying on a single supplier can be risky for large businesses. It’s important to have a diverse supplier network so that if one supplier has a delay or runs into issues, another can step in. This approach minimises disruption and ensures a steady flow of inventory.

Integrated Supply Chain Systems: Enterprise inventory systems should integrate seamlessly with supply chain management software to track shipments, manage lead times, and monitor supplier performance. This holistic view allows businesses to spot potential delays early and adjust their inventory strategies accordingly.

By leveraging automation, data analytics, and effective supplier management, enterprises can stay ahead of inventory challenges and ensure that stock is always where it needs to be—on the shelves and ready for customers.

Mobile and Barcode Scanning Integration

The Rise of Mobile Inventory Management Apps

As technology continues to evolve, mobile inventory management apps have become an essential tool for businesses of all sizes. These apps allow businesses to manage stock on the go, giving users the flexibility to track, update, and check inventory levels from their smartphones or tablets. With the rise of mobile solutions, business owners and staff no longer need to be tied to a desk or computer to manage their inventory.

Mobile apps streamline stock management by offering real-time updates, making it easier to maintain control over inventory, even when you’re out of the office or at multiple locations. For small businesses, it’s a cost-effective solution to keep tabs on stock, while larger enterprises benefit from improved mobility and reduced reliance on traditional systems.

How Barcode Scanning Improves Accuracy and Efficiency

Barcode scanning integration has dramatically improved accuracy and efficiency in inventory management. By scanning barcodes, businesses can instantly update stock levels, track product movements, and manage inventory with minimal effort and reduced risk of human error. Here’s how barcode scanning benefits inventory management:

Increased Accuracy: Manually entering product information into a system is prone to mistakes. With barcode scanning, stock data is recorded accurately and instantly, minimising the risk of discrepancies and ensuring reliable records.

Faster Stocktakes: Barcode scanning speeds up stocktakes by allowing staff to quickly scan each item without manually counting and entering data. This means less time spent on inventory checks and fewer disruptions to daily operations.

Real-Time Updates: When an item is scanned, the system updates inventory in real-time, providing an up-to-date view of stock levels. This allows businesses to make quicker, more informed decisions on reordering and stock allocation.

Reduced Labour Costs: Automating the inventory process with barcode scanning reduces the amount of manual labour required, saving time and cutting costs associated with human errors and inefficient processes.

Common Inventory Management Mistakes to Avoid

Overstocking vs. Undersocking: Striking the Balance

Overstocking and understocking are two critical inventory management issues that businesses need to balance. Overstocking ties up capital in unsold goods, increases storage costs, and risks product obsolescence. Conversely, understocking can lead to missed sales opportunities, dissatisfied customers, and lost revenue. The key is to find a balance that ensures you have enough stock to meet demand without overburdening your resources.

Ignoring Seasonal Trends or Market Changes

Failing to account for seasonal trends or market changes can result in significant inventory issues. Seasonal fluctuations, like holiday spikes or summer slowdowns, require proactive adjustments to inventory levels. Similarly, changes in market trends or consumer preferences must be monitored and incorporated into inventory planning. Ignoring these factors can lead to stock imbalances, missed sales, or excess inventory that’s difficult to shift.

Not Regularly Updating Your Stock Records

Neglecting to update stock records regularly can cause a range of problems, including inaccurate inventory levels, misplaced products, and poor decision-making. Regular updates are essential to reflect current stock levels, sales, and orders accurately. Failing to do so can lead to discrepancies between actual inventory and system records, affecting order fulfilment and overall inventory management efficiency.

Future Trends in Inventory Management

The Role of AI and Automation in Inventory Management

Artificial Intelligence (AI) and automation are transforming inventory management by enhancing efficiency and accuracy. AI-driven systems can analyse vast amounts of data to optimise inventory levels, forecast demand, and automate routine tasks. For example, AI algorithms can predict stock requirements based on historical sales data, current trends, and market conditions, enabling more accurate replenishment.

Automation tools streamline inventory processes, such as order processing, stock updates, and stocktakes, reducing the need for manual intervention. Automated systems can handle tasks like inventory counting and reordering with greater speed and fewer errors, freeing up staff to focus on more strategic activities. This shift not only boosts operational efficiency but also improves decision-making and responsiveness to market changes.

Predictive Analytics for Demand Forecasting

Predictive analytics is becoming a crucial tool for accurate demand forecasting. By leveraging historical sales data, market trends, and external factors like economic indicators or seasonal patterns, predictive analytics can forecast future demand with greater precision. This advanced forecasting helps businesses optimise inventory levels, reduce the risk of overstocking or stockouts, and improve customer satisfaction.

For instance, predictive models can identify patterns in consumer behaviour and adjust inventory strategies accordingly, ensuring that businesses are prepared for future demand spikes or downturns. This proactive approach allows companies to make informed decisions, allocate resources efficiently, and stay ahead of the competition.

How Sustainability and Eco-Friendly Practices Impact Inventory Choices

Sustainability and eco-friendly practices are increasingly influencing inventory management decisions. Businesses are adopting greener practices to reduce their environmental footprint and meet consumer demand for responsible sourcing and eco-conscious products. Here’s how these practices are shaping inventory choices:

Sustainable Sourcing: Companies are prioritising suppliers that adhere to sustainable practices, such as using recycled materials or minimising waste. This shift impacts inventory by favouring products with lower environmental impact and promoting more responsible production methods.

Reduced Packaging: Businesses are moving towards minimal and eco-friendly packaging to decrease waste and reduce their carbon footprint. This can affect inventory management by changing packaging requirements and potentially reducing storage space.

Efficient Logistics: Eco-friendly logistics practices, like optimising transport routes and using energy-efficient vehicles, are becoming more common. These practices help minimise carbon emissions and lower overall inventory costs by improving the efficiency of supply chains.

Circular Economy: The concept of a circular economy, which focuses on recycling and reusing materials, is influencing inventory strategies. Companies are exploring ways to extend product lifecycles and reduce waste through initiatives like product take-back programs and refurbishment.

Embracing sustainability not only aligns with corporate social responsibility goals but also can lead to cost savings, improved brand reputation, and increased customer loyalty.

Conclusion

As inventory management continues to evolve, staying ahead of the curve is crucial for businesses of all sizes. Embracing modern technologies like AI, automation, and predictive analytics can help you optimise stock levels, reduce costs, and improve efficiency. Additionally, integrating sustainable practices into your inventory strategy not only benefits the environment but also meets growing consumer expectations. By understanding and implementing these future trends, you can ensure your inventory management practices are both forward-thinking and effective.

Ready to take your inventory management to the next level?

Book a demo now to discover how WorkDash can help you optimise inventory, reduce costs, and stay ahead in today’s dynamic market. Explore our solutions and see how we can support your business’s growth and efficiency.