Table of Contents

As businesses strive for efficiency in increasingly competitive markets, one solution stands out: the ability to automate inventory management.

Leveraging an automated inventory management system not only optimises stock control but also minimises errors, improves customer satisfaction, and boosts profitability.

Let’s explore how inventory automation transforms operations for modern businesses.

What is inventory management automation?

To automate inventory management means using technology-driven systems such as inventory management software, IoT devices, and barcode technology to manage stock levels, monitor supply chains, and streamline order fulfilment processes. These automated systems enable businesses to move away from error-prone manual processes.

Key features of automated inventory systems:

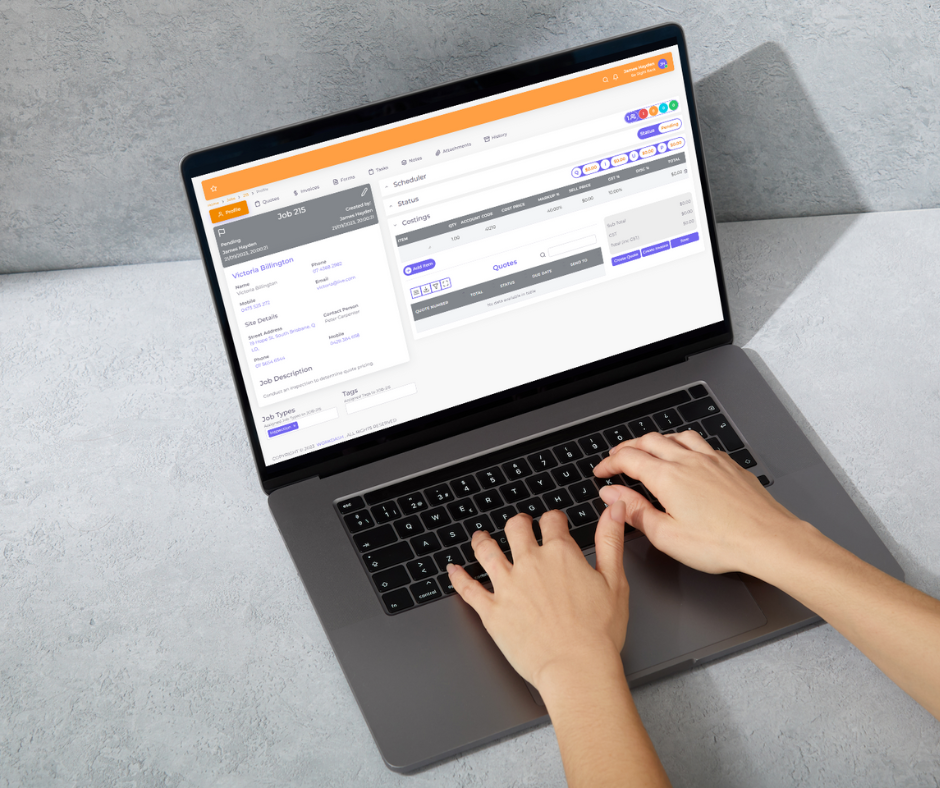

- Cloud-based inventory management software: Allows real-time tracking from any location.

- Barcode and RFID technology: Speeds up inventory tracking and improves accuracy.

- Integration with business tools: Connects with accounting and sales systems for seamless operations.

Read: How to Choose the Right Inventory Management Software

Industries benefiting from automation:

- Retail: Tracks high stock volumes and prevents stockouts.

- Manufacturing: Manages raw materials efficiently.

- E-commerce: Offers real-time visibility into stock levels and faster order processing.

Advantages of Inventory Automation

Accuracy and Error Reduction

Manual inventory management often leads to costly mistakes like miscounting, duplicate records, or stock misplacement.

How automation (in terms of automated technology and automated processes) ensures accuracy:

- Real-time inventory tracking: Immediate updates ensure stock records are accurate.

- Automated inventory control: Flags discrepancies early, reducing errors in inventory counts.

- Accurate inventory data: Provides insights into sales trends and stock utilisation.

Case study example:

An Australian electronics retailer implemented an automated inventory tracking system, reducing stock discrepancies by 40%. With barcoding and automated updates, the business saved thousands in mismanaged inventory costs.

Save Time and Money by Using Automated Inventory Management

Automating inventory processes eliminates repetitive manual tasks, saving time and reducing costs.

Time-saving benefits:

- Automated systems generate inventory alerts for restocking needs.

- Real-time monitoring eliminates the need for frequent manual audits.

Cost savings with automation:

- Avoiding overstocking frees up capital and reduces warehousing expenses.

- Minimising stockouts enhances customer satisfaction and avoids lost sales.

Optimise inventory levels:

With precise inventory forecasting, businesses achieve the right balance between supply and demand, ensuring they avoid excess inventory or shortages.

Improved Inventory Visibility with Automated Systems

Implementing an automated inventory management provides real-time visibility into stock data, which is a game-changer for businesses.

How automated systems provide better visibility:

- Centralised dashboards offer insights into inventory levels across multiple locations.

- Integration with warehouse management systems simplifies inventory operations.

Benefits of improved visibility:

- Enhanced supply chain coordination.

- Faster response times to changes in demand or disruptions.

Scalability for Growing Businesses

As businesses expand, managing inventory becomes more complex.

How automation supports scalability:

- Cloud-based systems handle high SKU volumes and multi-location inventories effortlessly.

- Scalable inventory solutions grow alongside the business.

Example:

A regional Australian fashion retailer used an inventory management solution to support its expansion into international markets. The software provided seamless global stock management and synchronised orders across time zones.

Integration with Other Systems: The Heart of Automation

Effective inventory management automation hinges on integration with other critical business systems.

Key integrations include:

- Accounting software: Tracks costs related to inventory in real time.

- Customer relationship management (CRM): Links inventory data to customer orders for personalised service.

- Order management processes: Ensures accurate stock allocation.

How integration improves operations:

By connecting systems, businesses eliminate redundancies, improve productivity, and gain valuable insights into their inventory processes.

Enhance Customer Satisfaction with Automated Inventory Management

Customers value efficiency and reliability. Using automated inventory management helps businesses deliver both.

How automation boosts customer satisfaction:

- Accurate stock availability: Avoids frustrating customers with out-of-stock notices.

- Faster order fulfilment: Automation streamlines the packing and shipping process.

Example:

An Australian online bookstore adopted an automated inventory system to manage stock across its warehouses. This system reduced delivery times by 30%, earning rave reviews from customers.

Sustainability Through Inventory Management Automation

Automation helps businesses minimise waste and adopt environmentally friendly practices.

Sustainable inventory management processes:

- Data-driven inventory forecasting reduces overproduction.

- Automated stock rotation minimises expired or unsold goods.

Adopting sustainable practices:

A local food supplier cut inventory waste by 25% by implementing automated inventory tracking with expiration date monitoring, ensuring timely usage of perishable goods.

Addressing Challenges in Using Automated Inventory Management Systems

While automation offers vast benefits, adopting new systems can present hurdles.

Common challenges:

- High initial costs: Advanced systems may require significant upfront investment.

- Learning curve for staff: Employees must be trained on new technology.

Overcoming obstacles:

- Opt for a cloud-based inventory management system with flexible pricing models.

- Provide robust training and ongoing support for employees.

Conclusion: Why Automate the Inventory Management Process?

Automating inventory management is no longer a luxury; it’s essential for staying competitive. By using an automated inventory management solution businesses can optimise inventory levels, improve customer satisfaction, and scale operations seamlessly. Whether you’re a small retailer or a large manufacturer, the time to invest in automation is now. Explore how automated inventory management software helps transform your business operations today.

Ready for better inventory control?

Book your demo with Workdash now and experience accurate and efficient inventory management.