Table of Contents

Barcode & Asset Tracking Made Simple: Never Lose Track of Your Equipment Again

Losing tools, equipment, or machinery is more than an inconvenience—it directly impacts productivity, costs, and trust across your organisation. From misplaced tools on job sites to outdated spreadsheets that don’t reflect reality, poor asset tracking creates friction in daily operations. The good news is that modern barcode and asset tracking solutions make it easy to know where every asset is, who has it, and when it’s due back.

This guide explains how barcode & asset tracking works, why spreadsheets fail, and how a modern asset tracking system inside WorkDash helps you never lose track of your equipment again. You’ll learn how to scan assets with a smartphone, use QR codes, run audits, and manage the full asset lifecycle—inside a flexible management software platform designed for service businesses, not an ERP.

Article Outline: Barcode & Asset Tracking Without the Headache

1. What Is Asset Tracking and Why Does It Matter?

2. Why Spreadsheets Fail at Asset Tracking

3. How Barcode Asset Tracking Actually Works

4. Barcode vs QR Code vs RFID: What Should You Use?

5. How an Asset Tracking System Improves Daily Operations

6. Tool Tracking and Equipment Tracking in the Field

7. Audits, Asset Data, and Lifecycle Management

8. Cloud-Based Asset Tracking with Mobile Apps

9. Asset Management Features That Drive Operational Efficiency

10. How WorkDash Delivers a Simple Asset Tracking Solution

What Is Asset Tracking and Why Does It Matter?

Asset tracking is the process of monitoring where each asset is, who is using it, and its current status. Assets can include tools and equipment, machinery, vehicles, and fixed asset items used across jobs and locations. Without a reliable tracking system, organisations experience asset loss, tool loss, delays, and unnecessary replacement costs.

A proper asset tracking system provides visibility and accountability. It allows teams to track assets in real time, maintain accurate asset data, and make informed decisions. For service businesses, asset tracking is not optional—it’s essential for operational efficiency and cost control.

Why Spreadsheets Fail at Asset Tracking

Many organisations still rely on a spreadsheet to manage assets. While spreadsheets may work at a very small scale, they quickly break down as asset counts grow or teams become mobile. Spreadsheets are static, prone to errors, and require manual updates that are often forgotten.

Without real-time updates, spreadsheets fail at keeping track of assets in the field. They cannot support scanning, alerts, or check-out workflows. As a result, businesses lose visibility, experience asset loss, and waste time reconciling records during audits.

How Barcode Asset Tracking Actually Works

A barcode asset tracking approach assigns a unique barcode to each asset. This barcode—often printed on durable barcode labels—is linked to an asset record inside a tracking system. When someone needs to use or move an asset, they simply scan the barcode.

Barcode scanning instantly updates the asset’s status and location. This eliminates manual data entry and ensures real-time accuracy. A barcode tracking system makes it easy to check out assets, assign tools, and know where equipment is at any moment.

Barcode vs QR Code vs RFID: What Should You Use?

When choosing an asset tracking solution, it’s important to understand the options. A barcode or QR code approach is the most practical for most service businesses. Barcodes are cost-effective, easy to print, and work with any smartphone or scanner.

QR code labels can store more data and are ideal for mobile scanning. RFID and tracker technologies offer automation but add cost and complexity. For most teams, barcode or QR code tracking delivers the best balance of simplicity, cost, and reliability.

How an Asset Tracking System Improves Daily Operations

A modern tracking system transforms how teams work. Instead of searching for tools or calling around, staff can instantly see asset availability. Alerts notify teams when assets are overdue or due back.

By centralising tracking and management, organisations streamline workflows and reduce downtime. The result is improved utilisation, fewer delays, and higher confidence that the right equipment is available when needed.

Tool Tracking and Equipment Tracking in the Field

Tool tracking and equipment tracking are especially critical for field teams. Tools often move between vehicles, sites, and team members, making them easy to lose. With barcode scanning on mobile devices, teams can check out assets on the go.

Using a smartphone or mobile app, staff can scan assets, update status, and attach notes or photos. This ensures tools and equipment are accounted for, reducing tool loss and keeping jobs on schedule.

Audits, Asset Data, and Lifecycle Management

Regular audit processes are essential for compliance and accuracy. An asset tracking system simplifies audits by providing instant access to asset data, usage history, and status changes.

Beyond audits, effective tracking supports lifecycle management. Businesses can track purchase dates, maintenance, utilisation, and retirement of each asset. This comprehensive view helps organisations plan replacements and optimise asset value over time.

Cloud-Based Asset Tracking with Mobile Apps

A cloud-based asset tracking solution allows teams to access data anywhere. There is no need for local servers or manual syncing. Updates happen instantly across the organisation.

With iOS and Android support, teams can use their smartphone as a scanner. This cloud-based asset approach ensures everyone works from the same source of truth, whether in the office or in the field.

Asset Management Features That Drive Operational Efficiency

Strong asset management goes beyond tracking location. Modern systems include asset tags, alerts, utilisation reporting, and workflow integration. These asset management features help businesses reduce waste and improve efficiency.

When asset tracking connects to workflows, teams can automate check-out, due back reminders, and approvals. This integration improves operational efficiency and ensures assets support—not hinder—business performance.

How WorkDash Delivers a Simple Asset Tracking Solution

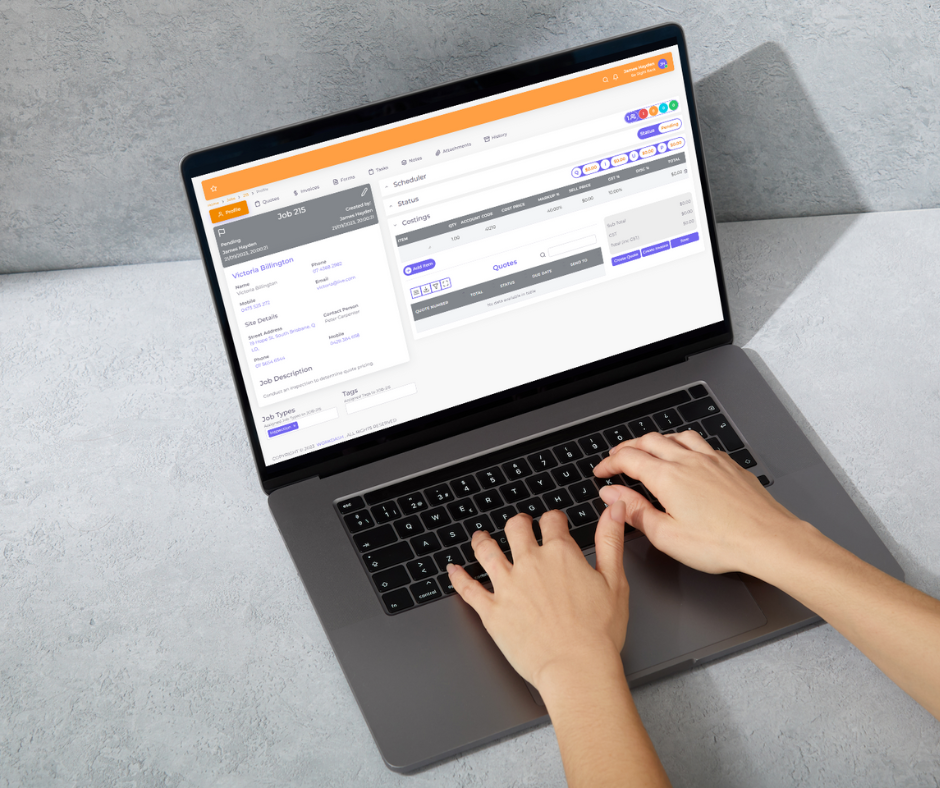

WorkDash provides asset tracking as part of a broader asset management platform inside its business management software. It allows businesses to tag assets, scan barcodes, and manage equipment without ERP complexity.

With WorkDash, organisations can start tracking assets quickly, assign tools to team members, run audits, and maintain full visibility. The platform is easy-to-use, mobile-friendly, and designed for real-world service operations—so you can never lose track of your equipment again.

Key Takeaways: Barcode & Asset Tracking Without the Chaos

Asset tracking prevents loss and improves accountability

Barcodes and QR codes offer a simple, cost-effective tracking solution

Spreadsheets fail at real-time asset management

Scanning updates asset status instantly

Tool tracking is critical for field teams

Cloud-based systems improve access and accuracy

Mobile apps turn smartphones into scanners

Audits become faster and more reliable

Asset lifecycle visibility improves planning and utilisation

WorkDash delivers asset tracking without ERP complexity