Table of Contents

How Service Businesses Track Assets, Equipment, and Maintenance Schedules the Smart Way

Keeping your tools, vehicles, and machinery running smoothly is at the heart of every service business. Whether you’re managing construction equipment, cleaning machines, or field service tools, having an organised asset management system ensures your team stays productive, downtime is reduced, and your clients get consistent, reliable service.

In today’s fast-paced industry, relying on spreadsheets or paper-based systems to manage equipment maintenance is a thing of the past. Businesses now use digital tools like WorkDash, a modern management solution designed for asset management, job tracking, and maintenance scheduling. This article explains why tracking assets, equipment, and maintenance schedules digitally helps service businesses reduce costs, prevent downtime, and maximise operational efficiency.

Why Equipment Maintenance Is the Backbone of Service Businesses

Every service business depends on reliable tools and machinery. When a piece of equipment breaks down, it doesn’t just stop work—it affects timelines, revenue, and reputation.

Implementing a structured equipment maintenance plan ensures every asset receives preventive maintenance before issues arise. Instead of reacting to problems, your team can schedule maintenance proactively, reducing equipment downtime and prolonging the lifespan of your equipment.

With WorkDash, you can track equipment usage, maintenance history, and inspection dates automatically—so no task is forgotten and every maintenance activity happens on time.

How Asset Tracking Software Helps You Keep Track of Everything

Keeping a detailed record of every asset in your business—from heavy equipment to tools—can be challenging. Without a proper asset tracking system, maintenance records and usage data often get lost.

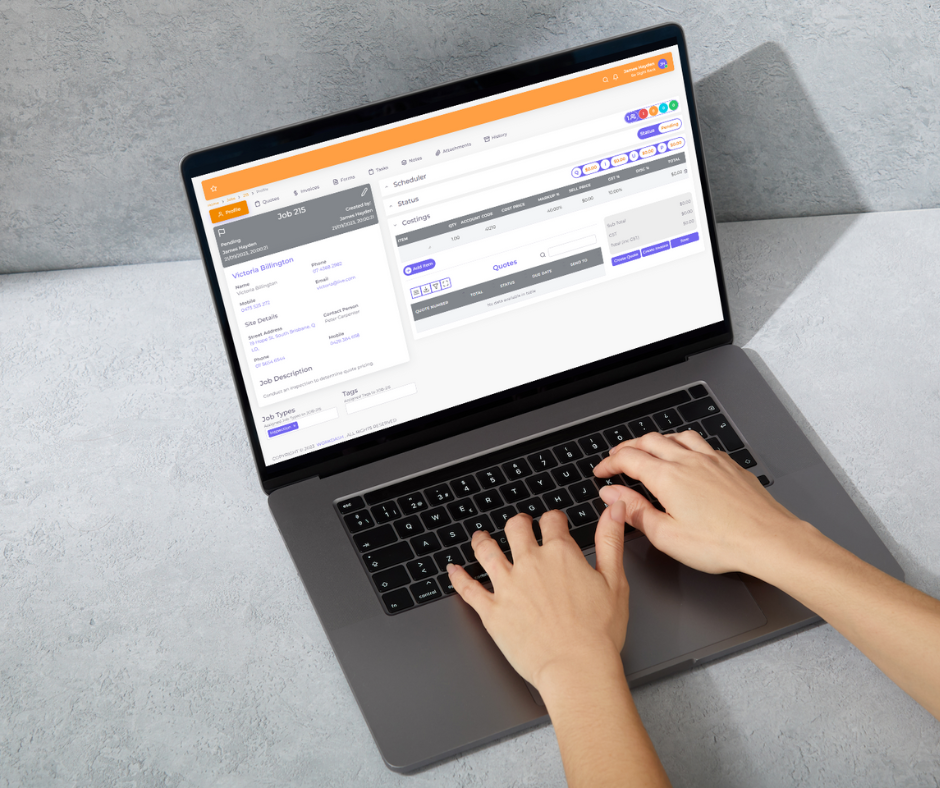

A digital tracking software like WorkDash provides real-time insight into each asset’s location, condition, and service history. It enables service teams to log maintenance tasks, upload inspection images, and note when specific repairs are due.

This management software helps you keep your equipment performing at its best while avoiding equipment breakdowns that lead to costly delays. With better asset management, you gain transparency, accuracy, and effective maintenance scheduling.

What Are the Benefits of a Structured Maintenance Schedule?

A maintenance schedule is the foundation of a well-run maintenance program. It dictates when, where, and how each asset is serviced.

Creating a maintenance plan helps your business:

Prevent unexpected equipment failure

Reduce unplanned downtime

Ensure compliance with safety standards

Extend asset lifespan

Improve maintenance management efficiency

A well-built maintenance schedule also allows you to plan ahead—so you can allocate resources, parts, and labour efficiently. WorkDash allows businesses to automate maintenance scheduling, set reminders for future servicing, and store all related documentation in one place.

How Preventive Maintenance Saves Time and Money

Preventive maintenance is one of the most effective maintenance strategies for service businesses. Instead of waiting for something to break, preventive maintenance scheduling ensures your team performs regular maintenance activities to stop problems before they happen.

By implementing preventive maintenance software like WorkDash, businesses can reduce maintenance costs, improve equipment performance, and increase reliability across all physical assets.

This proactive approach means fewer emergency repairs, reduced downtime, and better operational planning—all key elements for long-term business success.

How Asset Management Systems Keep Businesses Organised

A strong asset management system centralises all your maintenance operations, providing a complete view of your assets, their conditions, and their maintenance requirements.

With WorkDash, businesses can create detailed profiles for each asset, including serial numbers, purchase dates, warranty information, and service history. This ensures that maintenance work is scheduled accurately and performed efficiently.

In addition, a digital asset management system enables inventory management, helping you track spare parts, tools, and materials related to each maintenance task.

How to Build an Effective Equipment Maintenance Plan

An equipment maintenance plan is your roadmap for keeping assets in top condition. It defines maintenance procedures, inspection schedules, and key maintenance checkpoints.

When building your plan, consider:

The types of equipment in use

Manufacturer maintenance requirements

Environmental conditions (e.g. dust, moisture)

Frequency of use

Historical maintenance records

Using WorkDash, you can automate every aspect of your equipment maintenance plan, from assigning maintenance tasks to generating work order management reports. The system ensures all maintenance processes are logged, so you always have a complete record of what’s been done and when.

How a Computerized Maintenance Management System Improves Efficiency

A Computerized Maintenance Management System (CMMS) transforms how you handle maintenance management. It consolidates maintenance operations into one system—covering work orders, schedules, and performance tracking.

WorkDash functions as a modern alternative to a traditional CMMS, combining asset tracking, maintenance scheduling, and job allocation in a user-friendly management platform. It also helps with inventory management, ensuring your team never runs out of parts when performing maintenance tasks.

This integration allows you to streamline maintenance, automate reminders, and analyse data—helping you identify trends in equipment failure, maintenance costs, and maintenance effectiveness.

How Tracking Software Helps You Track and Manage Equipment Maintenance

For service businesses, tracking software is a game-changer. It helps you track and manage every maintenance operation while keeping your team aligned.

WorkDash’s tracking software simplifies tracking maintenance and ensures that every maintenance activity—from inspections to routine maintenance—is logged automatically. Each asset can be tagged with QR codes, allowing team members to access details about maintenance history, warranties, or parts needed.

This type of management solution reduces human error, speeds up reporting, and ensures maintenance management is handled consistently across all assets.

Why Preventive and Predictive Maintenance Are Essential for Asset Longevity

Preventive maintenance keeps things running smoothly, but predictive maintenance takes it a step further. By analysing real-time data, you can predict when equipment failure is likely to occur and schedule servicing accordingly.

WorkDash supports this maintenance strategy through analytics dashboards that show maintenance history, upcoming maintenance requirements, and usage patterns. This allows businesses to take action before equipment problems escalate—saving both time and money.

By combining preventive and predictive methods, you can develop a robust maintenance routine that keeps all equipment and machinery performing at peak efficiency.

How WorkDash Helps You Manage Assets, Equipment, and Maintenance

Managing equipment maintenance manually can be time-consuming and prone to errors. WorkDash brings everything together in a digital management software that allows businesses to schedule maintenance, perform maintenance tasks, and log updates in real time.

Here’s what WorkDash provides for service businesses:

A centralised asset management dashboard

Automated maintenance scheduling

Real-time job and inspection tracking

Full visibility of maintenance activities and records

Integration with inventory management and project management workflows

With these capabilities, WorkDash empowers service providers to manage equipment confidently, prevent downtime, and extend the life of their assets—all while reducing manual admin work.

How to Integrate Maintenance Management into Daily Operations

Integrating maintenance into your daily operations ensures maintenance practices aren’t just an afterthought—they become part of your team’s standard routine.

Using WorkDash, you can assign maintenance tasks to specific staff, track progress, and verify completion through mobile checklists or digital signatures. Automatic reminders ensure that no maintenance schedule is missed, while digital logs provide an auditable trail for compliance and reporting.

This proactive maintenance management approach ensures service businesses can operate safely, efficiently, and in compliance with all safety regulations.

Key Takeaways: Keeping Track of Assets and Maintenance the Smart Way

Asset management is critical for maintaining productivity and preventing costly downtime.

A clear maintenance schedule helps businesses perform maintenance tasks consistently and efficiently.

Preventive maintenance and predictive maintenance reduce equipment breakdowns and extend lifespan.

Digital tracking software like WorkDash simplifies tracking equipment maintenance and reduces manual work.

A Computerized Maintenance Management System or modern management platform ensures all data is centralised.

WorkDash enables businesses to schedule maintenance, monitor maintenance activities, and store maintenance records all in one place.

Proper asset management supports compliance, safety, and long-term sustainability.

Final Thoughts

Every service business that relies on tools, machinery, or vehicles needs a dependable way to manage assets and their maintenance schedule. WorkDash offers an intuitive, powerful maintenance management system that makes tracking assets, scheduling preventive maintenance, and analysing performance effortless.

By adopting WorkDash, your business gains full control over its asset management, ensuring your equipment runs efficiently, safely, and reliably—helping you streamline maintenance, reduce costs, and manage your equipment with confidence.

👉 Explore WorkDash.software today to discover how you can automate your equipment maintenance schedule, boost efficiency, and keep your business performing at its best.