Table of Contents

The automotive industry is currently undergoing significant transformations driven by technological advancements, regulatory pressures, and shifts in consumer demand. At the same time, the industry is grappling with a range of ongoing supply chain issues that threaten to disrupt the smooth functioning of operations. From shortages in critical components like semiconductors to logistical hurdles and geopolitical tensions, the automotive supply chain is under increasing pressure. Addressing these supply chain challenges will be pivotal for automotive suppliers and OEMs to remain competitive in an evolving market.

The Impact of Sustainability on the Automotive Supply Chain

Sustainability has become a central concern for many industries, and the auto industry is no exception, particularly in the context of building resilient supply chains. As environmental regulations become more stringent, manufacturers must rethink how they manage their supply chains to reduce their carbon footprint. This includes sourcing materials responsibly, adopting renewable energy sources, and reducing emissions across their manufacturing processes.

Automotive suppliers are also under pressure to innovate with more sustainable materials and manufacturing practices. The shift towards electric vehicles (EVs) further adds complexity to supply chain operations, as the raw materials for EV batteries, such as lithium, cobalt, and nickel, are often sourced from regions with unstable supply chains. Manufacturers must find ways to navigate these sustainability challenges while ensuring the smooth delivery of components and vehicles, thereby enhancing their risk management strategies in light of the changing market.

Managing Sustainability Risks

The automotive industry must address several sustainability-related risks within the supply chain. These include fluctuating raw material costs, concerns over resource scarcity, and the potential for supply disruptions due to natural disasters or geopolitical tensions, all of which contribute to the volatility in the supply chain. To mitigate these risks, automotive suppliers need to adopt more proactive and resilient strategies, including diversifying their sourcing and improving transparency in their supply chain management to address disruptions in the supply chain.

Blockchain for Supply Chain Visibility

Blockchain technology has emerged as a powerful tool for improving transparency and traceability in supply chains, including those in the auto industry, helping to mitigate supply problems. By providing an immutable ledger of transactions, blockchain allows manufacturers to track the journey of components from their suppliers to the final assembly plant. This technology can help reduce fraud, counterfeiting, and errors in the supply chain while improving efficiency and addressing challenges ahead.

As the automotive sector increasingly relies on global suppliers, maintaining visibility over each step of the supply chain becomes crucial. Blockchain can help automakers monitor the movement of parts, identify bottlenecks, and ensure timely delivery of parts, reducing the risk of disruptions in the supply chain and production interruptions.

The Role of Blockchain in Supply Chain Management

In the automotive industry, supply chain visibility is essential for managing the flow of parts globally, especially as the complexity of the supply chain grows with the rise of EVs and autonomous vehicles. By incorporating blockchain, manufacturers can gain real-time insights into their operations, improving decision-making and reducing costs.

Global Disruptions and Geopolitical Tensions

The automotive industry is highly sensitive to global disruptions, including trade wars, tariffs, and the challenges facing political instability. Geopolitical tensions, such as the ongoing conflict in Ukraine and shifting trade policies, can cause significant delays and shortages in the supply chain, exacerbated by the impacts of the covid-19 pandemic. The recent semiconductor shortage, exacerbated by these global disruptions, has highlighted the vulnerabilities of the automotive supply chain.

Manufacturers are facing difficulties in securing critical components from certain regions, which has led to delays in vehicle production and increased costs. With the world’s supply chains interconnected, even localized disruptions can have far-reaching consequences for the automotive sector.

Geopolitical Challenges and Supplier Relations

Automotive suppliers, particularly those in regions affected by conflict or trade barriers, are facing immense pressure. Tariffs on imports and exports can increase costs for automakers, reducing profitability. In addition, manufacturers must build more robust relationships with suppliers in stable regions to ensure the continuous flow of parts.

Component Shortages and the Semiconductor Crisis

One of the most critical ongoing supply chain issues facing the automotive sector today is the global semiconductor shortage. Modern vehicles rely on thousands of semiconductor chips for everything from engine control units to entertainment systems. The pandemic, combined with the surge in demand for consumer electronics, led to a shortage of these vital components.

The shortage has forced automakers to slow production and, in some cases, temporarily halt assembly lines. With no immediate solution to the chip shortage, the automotive industry faces a tough road ahead in meeting the growing demand for vehicles, especially as new models and features, such as advanced driver-assistance systems (ADAS), rely heavily on semiconductors.

Overcoming the Semiconductor Shortage

To address the ongoing semiconductor shortage, automotive suppliers must work closely with technology partners to secure a steady supply of chips. This may involve investing in local chip production facilities or forming strategic alliances with semiconductor manufacturers to efficiently meet the growing demand for EV adoption. In the long term, the industry may need to rethink its reliance on global supply chains for such critical components.

Cost Management and Inflationary Pressures

Inflationary pressures are impacting every aspect of the automotive supply chain, from raw materials to finished vehicles. In 2023, rising prices for steel, aluminium, and other essential materials put pressure on automotive suppliers and manufacturers to find cost-effective solutions. The automotive industry must navigate these increasing costs without passing them onto consumers, who are already feeling the strain of higher prices due to inflation.

Cost management will be a significant challenge in the lead-up to 2025, particularly as raw material prices fluctuate, labour shortages persist, and logistical costs rise. To ensure profitability, automakers must adopt more efficient manufacturing processes and focus on maintaining tight control over inventory and operational expenses.

Navigating Cost Management Challenges

Efficient cost management is essential for automotive suppliers looking to remain competitive. Manufacturers can achieve this by investing in automation and robotics to streamline production processes and reduce reliance on manual labour. Additionally, automakers must focus on improving their supply chain efficiency by leveraging data analytics and advanced technologies to better predict demand and optimize inventory levels.

EV Supply Chain Issues

The rapid growth of the electric vehicle (EV) market presents its own set of supply chain challenges, especially as the industry faces ongoing demand for millions of vehicles. The materials required for EV batteries are often sourced from limited geographic regions, making supply chains vulnerable to disruptions. Furthermore, the adoption of EVs requires automakers to rethink their entire production and supply chain strategies, from battery manufacturing to sourcing raw materials efficiently.

To ensure the growth of the EV market, automotive suppliers must invest in sustainable sourcing and production practices, while working to reduce the reliance on scarce materials like lithium and cobalt. Additionally, developing new battery technologies could help ease some of the pressure on supply chains in the long run.

The Shift to EV Supply Chains

As the automotive industry shifts towards electric mobility, automakers must adapt their supply chains to meet the unique demands of EV production and the volume of vehicles expected in the coming years. This includes securing a reliable supply of key materials, developing new battery technologies, and navigating the regulatory landscape for EV manufacturing.

Labour Issues and Talent Shortage

The automotive industry is facing a significant talent shortage, especially in critical areas such as supply chain management, engineering, and skilled labour. The pandemic exacerbated existing labour shortages, making it even harder for manufacturers to find qualified workers. As the automotive sector evolves with the advent of EVs, automation, and advanced manufacturing technologies, the demand for skilled workers will only increase.

Labour pains and skill gaps are becoming more evident, especially as the industry looks to meet the demands of electrification and technological innovation. Automotive suppliers must prioritise workforce development and invest in training programs to ensure they have the skilled talent necessary to drive the industry forward.

Addressing Labour Shortages in the Automotive Industry

To address the growing talent gap, automotive companies must focus on attracting and retaining skilled workers. This may involve offering competitive wages, investing in education and training, and creating a more inclusive work environment. Furthermore, automakers may need to embrace automation and AI to reduce their reliance on manual labour, making their supply chains more resilient to talent shortages.

Regulatory Compliance and Quality Control

The automotive industry is subject to stringent regulatory requirements, both at the national and international levels. Manufacturers must ensure their supply chains comply with environmental, safety, and quality standards. Failure to meet these regulations can lead to costly fines, reputational damage, and delays in production.

In addition to regulatory compliance, quality control is a major concern for automotive suppliers, particularly as they navigate the complexities of the covid-19 pandemic. As supply chains become more complex, maintaining consistent quality across all components becomes increasingly challenging. Suppliers must implement rigorous quality control measures to ensure that every part meets the required standards before it is delivered to automakers.

Ensuring Compliance and Quality

Automotive suppliers can improve regulatory compliance and quality control by adopting advanced technologies, such as AI-driven inspections and automated testing systems. These tools can help identify potential quality issues early in the production process, reducing the risk of defects and costly recalls.

The Impact of Supply Chain Issues on Automotive Business Startups

The automotive industry is one of the most competitive sectors in the global economy, and for automotive startups, entering this market is fraught with challenges. While these businesses aim to innovate and disrupt the traditional automotive ecosystem, they are significantly impacted by ongoing supply chain issues. From component shortages to logistical disruptions and technological barriers, automotive startups face unique difficulties that larger, established companies may be more equipped to manage. As we look toward 2025, addressing these challenges will be critical for new entrants aiming to survive and thrive in the automotive industry.

The Financial Impact on Automotive Startups

One of the most significant issues facing automotive startups today is cost management, particularly in light of the challenges in 2024. Given the volatile nature of global supply chains, automotive suppliers are often forced to deal with increasing prices for key components, such as raw materials and electronics. For a startup, this can strain cash flow, increase operational costs, and reduce profitability.

Without the leverage of established brands, startups may find themselves competing for the same limited resources, which can lead to delays in receiving parts or significantly higher prices for the same materials. In the long run, this could make it harder for new entrants to compete against legacy automakers that have more resources to weather supply chain disruptions.

Technology and Innovation as a Solution

Technology is at the heart of the automotive industry’s future, and startups are uniquely positioned to leverage innovations to streamline their supply chains. By adopting cutting-edge technologies like artificial intelligence (AI), machine learning (ML), and Internet of Things (IoT), automotive startups can gain better insights into their supply chain operations, forecast demand more accurately, and improve inventory management.

Investing in automation and digital tools can also help startups reduce reliance on manual processes, increasing efficiency and mitigating the risk of human error. Additionally, these technologies can provide real-time data on inventory levels, component status, and production timelines, enabling startups to make more informed decisions and reduce the impact of supply chain disruptions.

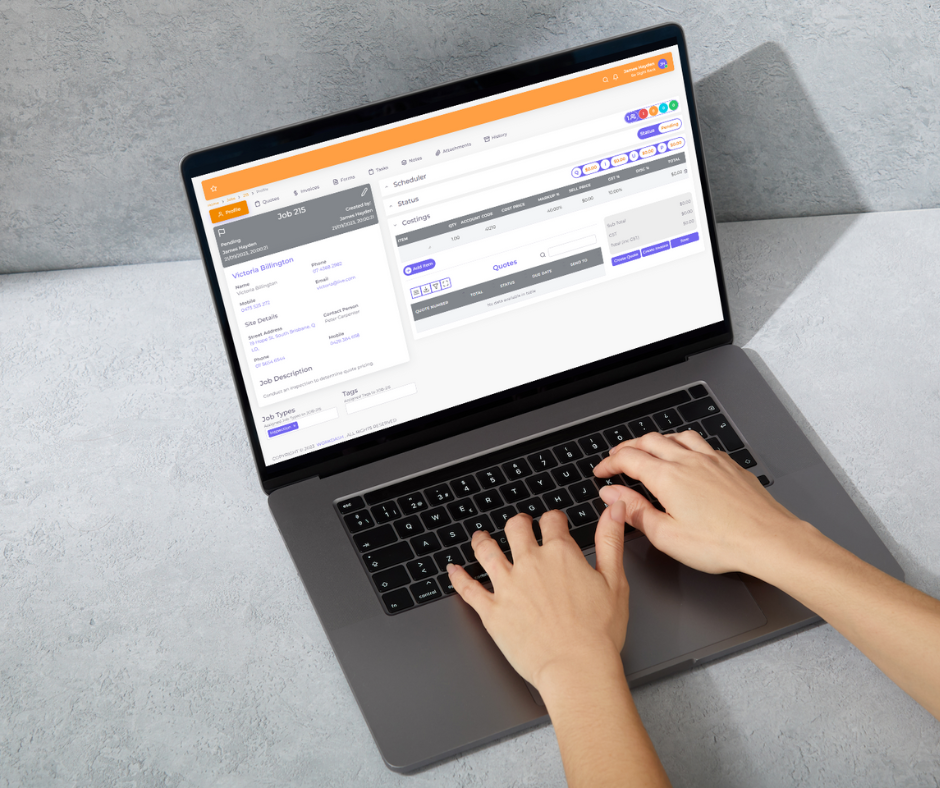

How WorkDash Helps Automotive Startups and Smaller-Scale Businesses

Startups and smaller-scale businesses in the automotive and other industries often face unique challenges when managing their supply chains, particularly when dealing with inventory issues. Limited resources, lack of robust infrastructure, and the complexities of handling multiple suppliers and fluctuating stock levels can all hinder smooth operations. WorkDash’s cloud-based inventory management system offers a comprehensive solution that streamlines inventory processes and significantly reduces the risks associated with supply chain problems.

WorkDash is the best indicator of how technology can streamline operations in the automotive industry. It is a business management software for automotive businesses with its robust features and great value for money.

Conclusion

The automotive industry faces a complex and evolving set of challenges as it navigates the intricacies of the global supply chain. From sustainability issues to labour shortages and technological barriers, automotive suppliers must adapt to a rapidly changing landscape.

Addressing these supply chain issues will be crucial for the industry’s resilience and long-term success. By embracing new technologies, improving supply chain visibility, and investing in talent and sustainability, automakers can build more efficient and resilient supply chains that will help them thrive in an increasingly competitive and volatile market.

Leverage WorkDash now! Subscribe for free today!