Table of Contents

In today’s interconnected world, global supply chains play a crucial role in modern business operations. However, disruptions in the supply chain process can lead to supply chain bottlenecks, causing delays, increased costs, and inefficiencies. These bottlenecks are particularly challenging for small businesses, which often lack the resources and flexibility to navigate supply chain bottlenecks effectively.

The COVID-19 pandemic highlighted the vulnerabilities of global supply chains, leading to widespread supply chain issues and shortages of certain products. From procurement and supply chain disruptions to delivery delays, businesses worldwide struggled to keep up with demand. Even beyond the coronavirus pandemic, businesses continue to face supply bottlenecks due to factors such as supplier constraints, transportation delays, and inventory-related bottlenecks.

Understanding the common causes of supply chain bottlenecks and implementing strategies to prevent bottlenecks is essential for maintaining a flexible supply chain. By identifying bottlenecks in their supply chain, businesses can improve supply chain performance, eliminate bottlenecks, and ensure smooth supply chain operations.

In this article, we will explore the key factors contributing to supply chain bottlenecks, their impact on small businesses, and effective strategies to overcome supply chain bottlenecks and build a resilient supply chain.

What are supply chain bottlenecks?

A supply chain bottleneck occurs when a disruption or inefficiency in the supply chain process slows down operations, leading to delays, shortages, and increased costs. These bottlenecks can arise at any stage, from procurement and production to distribution and delivery. The impact of supply bottlenecks became more evident during the COVID-19 pandemic, which exposed vulnerabilities in global supply chains and led to widespread supply chain disruptions.

How Bottlenecks Arise in the Supply Chain Process

Supply chain bottlenecks can develop at various points due to different factors, such as supplier issues, raw material shortages, labour constraints, or transportation disruptions. A bottleneck in procurement may occur when a supplier cannot meet demand, while a production bottleneck may arise due to equipment failure or limited workforce availability. Delays in logistics, including port congestion and delivery slowdowns, can also create bottlenecks throughout the supply chain.

Natural disasters, political instability, and fluctuations in supply and demand further contribute to supply chain challenges, making it crucial for businesses to identify potential bottlenecks early and develop contingency plans to mitigate risks.

The Impact of Supply Chain Bottlenecks on Business Operations

A supply chain bottleneck can have significant consequences on supply chain efficiency and overall business performance. Delivery times may be extended, affecting customer satisfaction and reducing trust in a brand. Production delays can lead to increased costs, as businesses may need to find alternative suppliers or expedite shipments to meet deadlines.

Moreover, supply bottlenecks can cause inventory management issues, leading to excess stock in some areas while leaving other parts of the supply chain struggling with shortages. These inefficiencies highlight the importance of effective supply chain management, including supply chain visibility, streamlining operations, and adopting a resilient supply chain strategy to overcome supply chain bottlenecks and ensure business continuity.

By identifying common causes of supply chain bottlenecks and taking proactive steps to navigate supply chain bottlenecks, businesses can strengthen their supply chains and prevent disruptions that negatively impact operations, profitability, and customer satisfaction.

Common Causes of Supply Chain Bottlenecks for Small Businesses

Understanding the common causes of these disruptions is key to keeping operations running smoothly. Here are the common causes of supply chain bottlenecks:

Supply and Demand Imbalances

Fluctuations in market demand are one of the most common causes of supply chain bottlenecks. Sudden spikes in consumer demand can lead to supply constraints, making it difficult for businesses to secure inventory. On the other hand, unexpected drops in demand can result in overstocking issues, increasing storage costs and waste. To navigate supply chain bottlenecks, small businesses need agile supply strategies that allow them to quickly adapt to market changes.

Supplier Issues

Reliance on a limited number of suppliers can make small businesses vulnerable to disruptions. Supplier delays, raw material shortages, and price surges can create bottlenecks in your supply chain, affecting production and deliveryschedules. To prevent supply chain bottlenecks, businesses should diversify suppliers, negotiate better contracts, and implement supply chain kpis to monitor supplier performance.

Disruptions in the Supply Chain

External factors such as natural disasters, geopolitical issues, and pandemics can significantly impact supply chains. The COVID-19 pandemic in 2021 exposed many supply chain weaknesses, causing severe bottlenecks across industries. These disruptions can lead to shortages, delays, and increased costs. Identifying and addressing these bottlenecks through risk management and contingency planning can help businesses remain resilient.

Production Bottleneck

Inefficiencies in manufacturing and procurement can slow down the entire supply chain process. Bottlenecks are often caused by outdated equipment, labour shortages, or inefficient workflows, limiting production output. Resolving supply chain inefficiencies by investing in automation, streamlining processes, and adopting supply chain optimization techniques can improve overall supply chain performance.

Inventory-Related Bottlenecks

Poor inventory management system practices can create serious challenges for small businesses. Understocking leads to lost sales and dissatisfied customers, while overstocking ties up capital and increases storage costs. Many supply chain bottlenecks can also stem from improper demand forecasting and a lack of real-time inventory tracking. Implementing supply chain planning and leveraging supply chain data can help businesses eliminate bottlenecks and maintain a flexible supply chain.

By understanding these common supply chain bottlenecks, small businesses can take proactive steps to address supply chain challenges, prevent bottlenecks, and improve efficiency across the supply chain.

How to Overcome Supply Chain Bottlenecks

Supply chain bottlenecks can disrupt business operations, leading to delays in delivery, increased costs, and unsatisfied customers. To navigate supply chain bottlenecks, businesses must adopt strategic measures to enhance efficiency, flexibility, and resilience. Below are key steps to overcome supply chain bottlenecks effectively.

Improve Supply Chain Management

A well-structured supply chain management system ensures smooth operations and prevents disruptions. Businesses should:

- Assess their supply chain networks regularly to identify weak links.

- Implement supply chain optimization strategies to increase efficiency.

- Utilize real-time supply chain data to track inventory, shipments, and supplier performance.

By doing so, businesses can prevent supply chain bottlenecks and enhance the overall flow of goods.

Streamline Procurement and Delivery Processes

Every supply chain relies on efficient procurement and delivery systems. Businesses can eliminate inefficiencies by:

- Negotiating better contracts with multiple suppliers to avoid dependency on a single source.

- Improving demand forecasting to ensure stock availability and reduce delays.

- Investing in digital tracking systems to monitor shipments and anticipate delays.

Addressing procurement and delivery inefficiencies can help businesses overcome supply chain bottlenecks and maintain a successful supply chain.

Build a Flexible Supply Chain

A flexible supply chain allows businesses to adapt quickly to disruptions. This involves:

- Diversifying suppliers to mitigate risks from geopolitical issues or global supply chain disruptions.

- Creating alternative sourcing strategies to ensure continued operations during a pandemic or economic downturn.

- Adopting automation and AI-powered analytics to detect inefficiencies and make data-driven decisions.

A flexible supply chain ensures that businesses remain agile and can mitigate bottlenecks effectively.

Enhance Inventory Management

Poor inventory management is a common cause of supply bottlenecks. Businesses should:

- Use an inventory management system to maintain accurate stock levels.

- Implement just-in-time (JIT) inventory practices to reduce excess stock while ensuring sufficient supply.

- Leverage predictive analytics to forecast demand and avoid overstocking or shortages.

Efficient inventory management can help businesses eliminate bottlenecks and maintain smooth operations.

Collaborate with Supply Chain Professionals

Supply chain professionals have the expertise to identify inefficiencies and suggest improvements. Businesses can:

- Partner with logistics experts to optimise transportation and distribution.

- Work with technology providers to automate and digitise supply chain processes.

- Engage in industry collaborations to stay updated on best practices and emerging trends.

By addressing supply chain issues with expert guidance, businesses can improve overall supply chain efficiency.

Conclusion: Overcoming Supply Chain Bottlenecks for Long-Term Success

To overcome supply chain bottlenecks, businesses must identify the root cause, adopt technology-driven solutions, and maintain flexibility in sourcing and inventory management.

Implementing these strategies will help businesses navigate supply chain bottlenecks, reduce disruptions, and ensure a successful supply chain. By continuously identifying and addressing these bottlenecks, businesses can strengthen their operations and enhance customer satisfaction by ensuring timely deliveries and reliable supply chains.

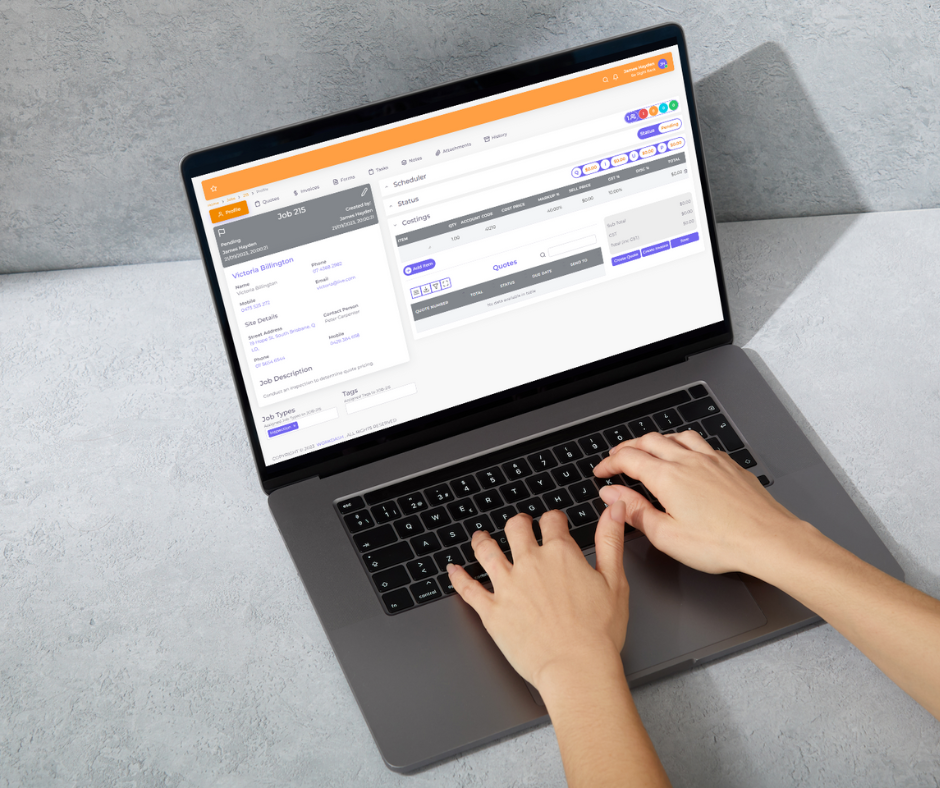

Having the right tools can make all the difference

Navigating supply chain bottlenecks requires smart strategies, and having the right tools can make all the difference. WorkDash’s inventory management feature helps small to medium businesses streamline stock control, optimise procurement, and prevent overstocking or shortages.

With real-time tracking and automation, businesses can stay ahead of disruptions and maintain a smooth, efficient supply chain.

Tired of inventory headaches?

Book your Workdash demo today and take control with accurate, efficient inventory management!